Product Center

Graphene-coated aluminum foil for supercapacitors/power batteries

Category:

Keywords:

Product Description

A1 layer

Etching layer

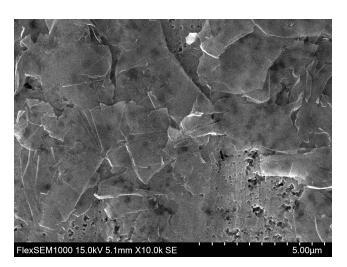

Graphene layer

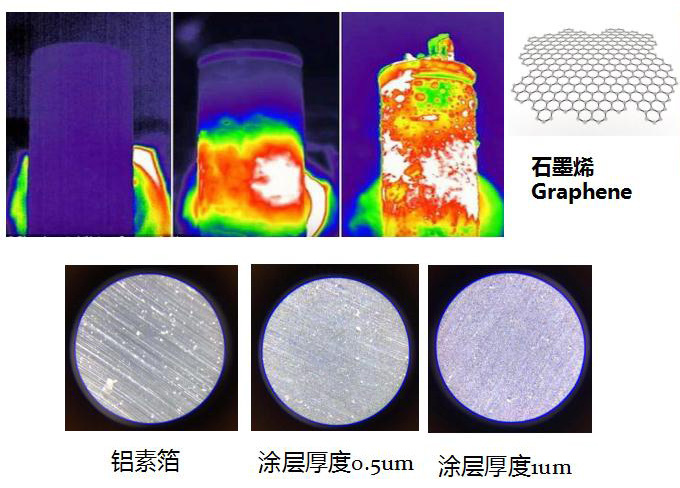

Utilizing carbon's excellent conductivity, heat dissipation, and chemical resistance.

Provides excellent conductivity, significantly reducing the contact resistance between the positive/negative electrode materials and the current collector.

Improves adhesion, increases thermal conductivity, and enhances product stability.

Specifications:

ⅠFirst code | ⅡSecond code | Ⅲ、ⅣThird, Fourth code | ⅣFourth code |

| Coating raw materials | Binder type | Original foil thickness | Coating thickness (double-sided) |

| Coating raw materials | Binder type | Aluminum foil thickness | Graphene thickness |

Graphene | Water-based binder | 20:20um | 1:Double sided below 1um |

| Carbon nanotubes | Polyvinylidene fluoride | 16:16um | 2:Double sided below 2um |

| Carbon powder | Thermosetting binder | 15:15um | Customized thickness |

| Battery cathode dedicated binder | 12:12um | ||

Hot melt adhesive |

Fast charging solution and adhesion solution - graphene coated aluminum foil

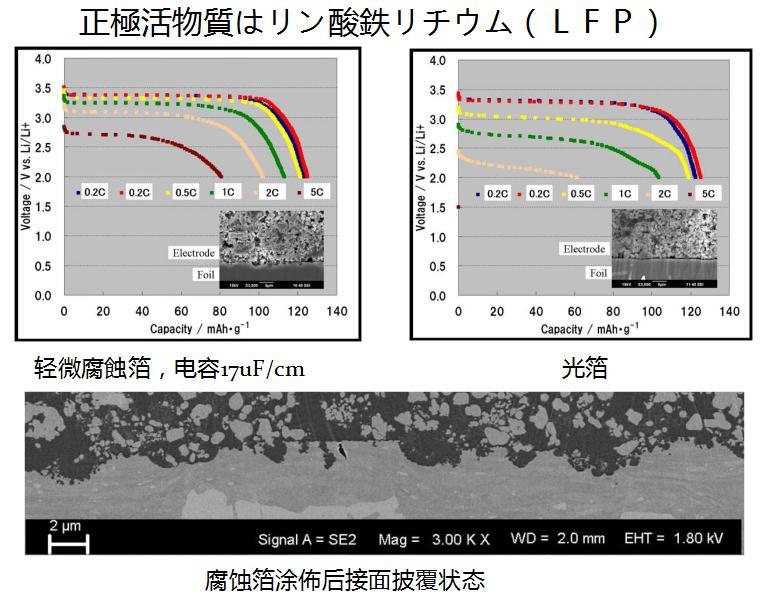

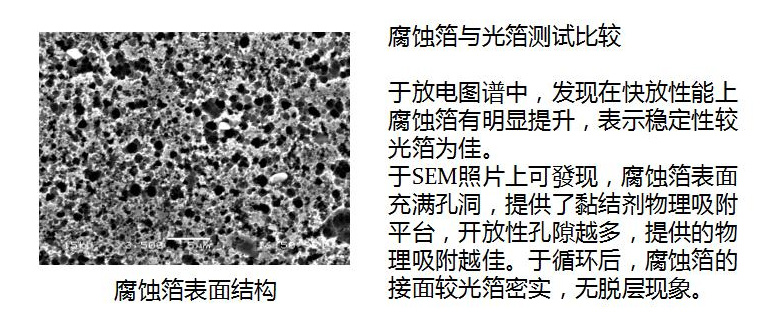

Graphene-coated foil - As a lithium-ion battery substrate, it is mainly composed of a binder and graphene. Through graphene's excellent theoretical conductivity (106S/m) and thermal conductivity (5000w/m.k: X-Y plane), it can effectively collect the electrical energy and heat generated during the charging and discharging process of the electroactive material.

Carbon-coated foil (graphene water-based binder) GW series

| Product Model | Thickness/Double-sided total (um) | Unit surface density (g/M2) | Tensile strength (Kg/cm) | Bending resistance | Base foil dyne 56 | Carbon layer dyne 56 | Tape >8N/cm | Solvent resistance (NMP, BAC) | Water resistance |

| GW-121 | 1 | 0.3~0.7 | 3±0.3 | 250< | Pass | Pass | Pass | Pass | Pass |

| GW-122 | 2 | 0.6~1.4 | 3±0.3 | 250< | Pass | Pass | Pass | Pass | Pass |

| GW-161 | 1 | 0.3~0.7 | 3±0.3 | 75< | Pass | Pass | Pass | Pass | Pass |

| GW-162 | 2 | 0.6~1.4 | 3±0.3 | 75< | Pass | Pass | Pass | Pass | Pass |

| GW-121 | 1 | 0.3~0.7 | 3±0.3 | 250< | Pass | Pass | Pass | Pass | Pass |

| GW-122 | 2 | 0.6~1.4 | 3±0.3 | 250< | Pass | Pass | Pass | Pass | Pass |

| GW-161 | 1 | 0.3~0.7 | 3±0.3 | 75< | Pass | Pass | Pass | Pass | Pass |

| GW-162 | 2 | 0.6~1.4 | 3±0.3 | 75< | Pass | Pass | Pass | Pass | Pass |

Coating thickness and coating area can be adjusted according to customer needs, mainly using 1070A aluminum material

Carbon-coated foil (GW graphene water-based binder) (TM carbon tube hot melt adhesive system)

| Product Model | Thickness/Double-sided total (um) | Unit surface density (g/M2) | Tensile strength (Kg/cm) | Bending resistance | Base foil dyne 56 | Carbon layer dyne 56 | Tape >8N/cm | Solvent resistance (NMP, BAC) | Water resistance |

| GW-221 | 1 | 0.3~0.7 | 3.2±0.3 | 70< | Pass | Pass | Pass | Pass | Pass |

| GW-222 | 2 | 0.6~1.4 | 3.2±0.3 | 70< | Pass | Pass | Pass | Pass | Pass |

| GW-301 | 1 | 0.3~0.7 | 4.5±0.3 | 85< | Pass | Pass | Pass | Pass | Pass |

| GW-302 | 2 | 0.6~1.4 | 4.5±0.3 | 85< | Pass | Pass | Pass | Pass | Pass |

| GW-221 | 1 | 0.3~0.7 | 3.2±0.3 | 70< | Pass | Pass | Pass | Pass | Pass |

| GW-222 | 2 | 0.6~1.4 | 3.2±0.3 | 70< | Pass | Pass | Pass | Pass | Pass |

| GW-301 | 1 | 0.3~0.7 | 4.5±0.3 | 85< | Pass | Pass | Pass | Pass | Pass |

| GW-302 | 2 | 0.6~1.4 | 4.5±0.3 | 85< | Pass | Pass | Pass | Pass | Pass |

Used for lithium battery characteristic testing

Previous page:

Next page:

Previous page:

Next page:

Product Inquiry

Contact Us

惠州市冠业新材料科技有限公司

86-0752-6221000

No. 332, Boxin Road, Boluo County, Huizhou City (Intercontinental High-tech Industrial Park)

WeChat Official Account

Copyright © AFT ELECTRONIC CO., LTD.. All rights reserved

Power by:www.300.cn | SEO | Privacy Policy